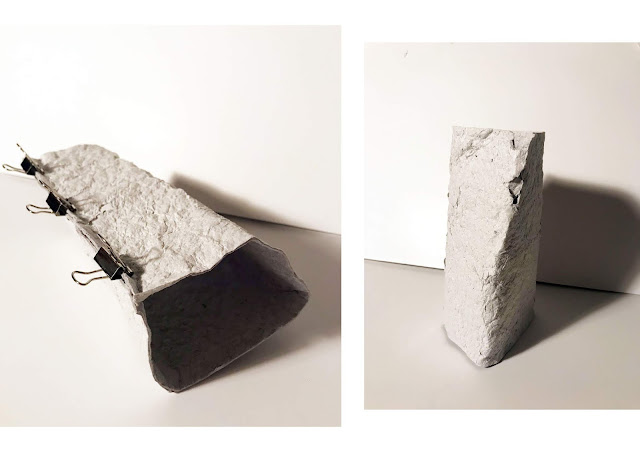

PULP contemporary research

https://www.upcyclist.co.uk/2017/02/10-eco-chic-lighting/ https://www.upcyclist.co.uk/2016/01/vessels-made-from-paper-pulp-by-debbie-wijskamp/ https://www.eternitystew.com/Formulations https://www.eternitystew.com/Paper-Islands Sculptures are made with paper fiber and plaster or paper pulp; acrylic paint, cut painted paper, metal leaf, and pigmented concrete.